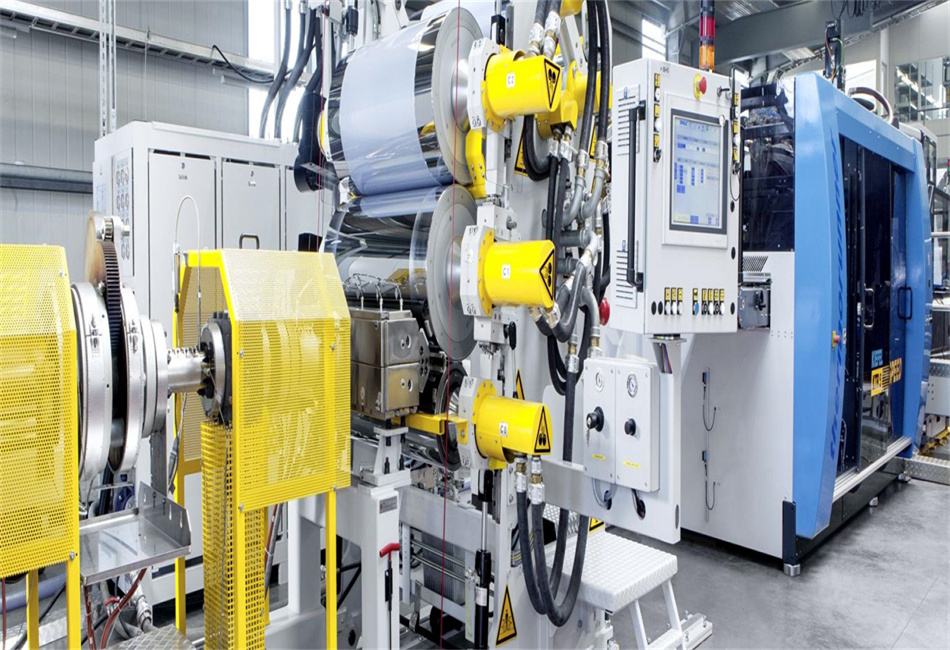

Bi-oriented Stretch Films :BOPP/BOPET/BOPA/Optical film,Battery Separator Film

Casting Film: CPP CPE film, Plast Sheet :ABS PVC,HDPE,LLDPE,PET,PP Sheet .

Casting Film Roller :

Casting Pressure Roller, we also not only offer Casting roller, Casting Cleaning roller, Corona Treater Roller, Corona Treatment Nip Roller

Bi-oriented Film Roller :Water Tank Fluted Roller, Chill Roller, Stripping Roller,Dehyration Roller,MDO Preheating Roller,MDO Stretching Roller,Corona Treater Roller, Corona Treatment Nip Roller,Pull Roller,Vacuum Suction Roller,Carbon Fiber Floating Roller, MDO Nip Roller, Carbon Fiber Contact Roller, Carbon Fiber Tension Roller,Water Tank Fluted Roller,Carbon Fiber Slitter Roller.

1. Support and Transport: In the film winding machine, the rollers are mainly responsible for supporting and transporting the plastic film. They carry the film during rotation, ensuring that the film can be wound smoothly, thereby making the storage and transportation of the film more convenient and effective,

,2. Winding: The roller plays a central role in the winding process. By winding the film, the collection and arrangement of the film are achieved. The roller of the winding machine can adjust the winding speed, tension and winding diameter through the control system to ensure the stability of the winding1.

3. Maintain film quality: The adsorption roller is used in film production to maintain the integrity of the appearance and thickness uniformity of the produced products, effectively ensuring product quality. It uses special suction elements to tightly combine the film with the inside of the drum to drive away air and improve product quality.

4. Improve work efficiency: The flexibility of the adsorption roller allows it to adjust the adsorption force of the internal suction element according to the weight of the carrier to meet actual production needs, thereby improving work efficiency. At the same time, the dust-proof device inside the adsorption roller reduces the entry of dust, maintains the cleanliness of the internal parts of the equipment, and helps maintain the operating performance of the equipment.

5.Special application: In the production of polyimide film, the corona roller improves its printability and adhesion by treating the film surface, which is crucial for improving the performance of the film

Welcome to visit us roller for Bi-oriented Stretch Film line

Roller for Cast Film and Plastic Sheet line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.